Chapters

Electric motors are incredible devices that are crucial in our modern world. From powering household appliances to propelling electric cars, these engineering marvels convert electrical energy into mechanical motion. In this article, we will delve into the workings of electric motors, explore their essential components, and uncover their versatile applications in various devices.

What is an Electric Motor?

An electric motor is a device that converts electrical energy into mechanical energy. It does this by using the power of magnets and electricity. Inside the engineotor, a unique coil of wire carries an electric current. Electricity flows through the coil and creates a magnetic field around it.

At the same time, a permanent magnet has its magnetic field nearby. The two magnetic fields interact with each other. These interactions between the magnet and the coil create forces that rotate the coil, causing the motor to move.

When a coil of wire carries an electric current in a magnetic field, a force acts on it that makes it rotate. This pushing force can be utilized to create something called an electric motor.

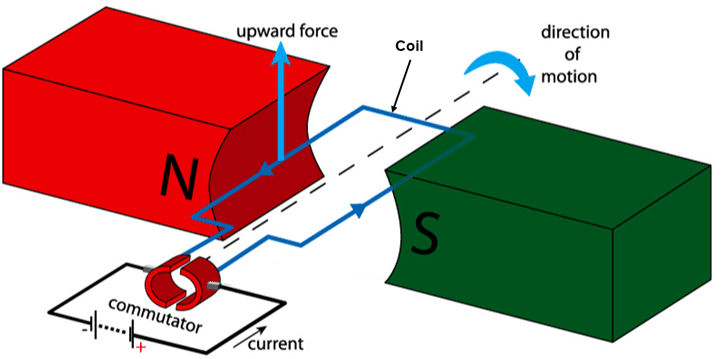

The below diagram shows what an electric motor looks like:

We have a special coil made of wire that can spin freely between two magnets with opposite poles facing each other. At each end of the coil, we have something called a split ring commutator. This commutator is like a switch that changes the direction of the electric current.

One side of the commutator is connected to the positive side of a direct current (DC) power supply, while the other is connected to the oppositive.

Components of an Electric Motor

An essential electric motor has some vital parts that work together to make it function:

- Permanent Magnet: There is a special magnet that stays fixed in place. It has a magnetic field that doesn't change.

- Armature or Rotor: This part comprises a thin copper wire wrapped around an iron core. When an electric current flows through the wire, it turns into an electromagnet. In a simple motor, the wire is formed into a loop shape.

- Commutator: The commutator is like a copper ring divided into two halves. In a simple electric motor, each half of the commutator is connected to the ends of the wire loop. Usually, in practice, these halves are connected to the axle.

- Brushes: Special brushes make contact with the wire loop or armature. They help connect the wire loop to the power supply.

- Axle: The commutator is attached to the axle. The axle is responsible for transferring the rotational motion created by the motor.

- Power Supply (Battery): To make the motor work, it needs a power supply, usually a battery, which provides the electric current required to energize the wire loop and create the magnetic field.

Combining these parts allows the electric motor to generate movement when the current flows through the wire loop, creating magnetic forces that interact with the fixed magnet, ultimately causing the motor to rotate.

Working on a DC Electric Motor

A DC electric motor converts electrical energy into mechanical motion or movement. It consists of key components, including a permanent magnet, an armature (coil of wire), a commutator, brushes, and an axle. Here is how this motor works:

- The permanent magnet provides a fixed magnetic field in the motor.

- The armature, made of a coil of wire, is connected to the commutator and can freely rotate between the magnet's poles.

- When an electric current flows through the armature, it creates a magnetic field around it.

- The commutator, split into two halves, reverses the direction of the electric current in the armature as it rotates.

- The brushes contact the commutator and connect it to a power supply, usually a battery.

- As the electric current flows through the armature, the interaction between the magnetic fields of the permanent magnet and the armature's field creates forces.

- These forces cause the armature to rotate, resulting in the rotational motion of the motor.

- The axle is attached to the commutator and transfers the rotational motion of the armature to the motor's output, such as a fan or wheels.

In short, a DC electric motor utilizes the interaction between magnetic fields and the rotation of the armature to convert electrical energy into mechanical motion.

Increasing the Power of an Electric Motor

To make an electric motor more powerful, we can do the following:

- Increase the number of turns in the coil: In the animation, having two loops of wire instead of one will make the motor stronger.

- Use a soft iron core: By wrapping the wire around a soft iron core, the magnetic field becomes stronger, leading to a more powerful motor.

- Replace the permanent magnet with an electromagnet: Instead of a fixed magnet, we can use an electromagnet. It can produce a stronger magnetic field because we can control the electric current flowing through it.

- Add extra coils: Similar to having two separate wire loops, as shown in the animation; we can wind additional coils around the core. This would require splitting the commutator into four parts, allowing for more turns and increasing the motor's power.

By implementing these techniques, we can enhance the power and performance of an electric motor.

Use of Electric Motors in Different Devices

Electric motors are versatile devices, and their application extends to many areas. These examples highlight the common usage of electric motors in devices we may encounter daily.

- Fans: Electric motors are used in fans to generate the rotational motion of the blades, providexcellentcool air circulation.

- Washing Machines: Electric motors power the drum in washing machines, allowing it to rotate and agitate the clothes during the washing process.

- Electric Cars: Electric motors play a crucial role in powering electric vehicles, driving the wheels by converting electrical energy from the battery into mechanical energy.

- Blenders: Electric motors rotate the blades, enabling the mixing and blending of ingredients.

- Conveyor Belts: Electric motors drive conveyor belts in industries, facilitating the movement of goods and materials along the production line.

- Electric Toothbrushes: Electric motors are employed in electric toothbrushes to generate the oscillatory motion of the brush head, aiding in effective teeth cleaning.

- Remote-Controlled Cars: Electric motors power the wheels in remote-controlled cars, enabling them to move forward, backwards, and steer.

Summarise with AI:

You are the best,, coz you have gotten content about the topics

Hello ! Glad to hear that you’ve found the content useful!