Chapters

What are Generators?

Generators are essential devices that convert mechanical energy into electrical energy. They act as the heart of our power infrastructure, providing electricity for everything from small portable tools to entire cities via large-scale power stations.

The fundamental principle behind every generator is electromagnetic induction. This process involves moving a conductor, such as a coil of wire, through a magnetic field. When the coil rotates, it "cuts" through the magnetic flux lines. According to Faraday's Law, this relative motion induces an electromotive force (EMF), or voltage, which drives an electric current through the wire.

The Components of a Generator

While different models vary in size, most generators share a core set of components:

- The Stator: The stationary part of the generator. It provides a constant magnetic field, typically using permanent magnets or electromagnets.

- The Rotor (Armature): The rotating component consisting of coils of wire. As this part spins, induction occurs.

- Prime Mover: The source of mechanical energy that spins the rotor. Examples include steam turbines (in nuclear or coal plants), water turbines (hydroelectric), or internal combustion engines (portable diesel generators).

Types of Generators

Generators are categorized based on the type of electrical output they produce: Alternating Current (AC) or Direct Current (DC).

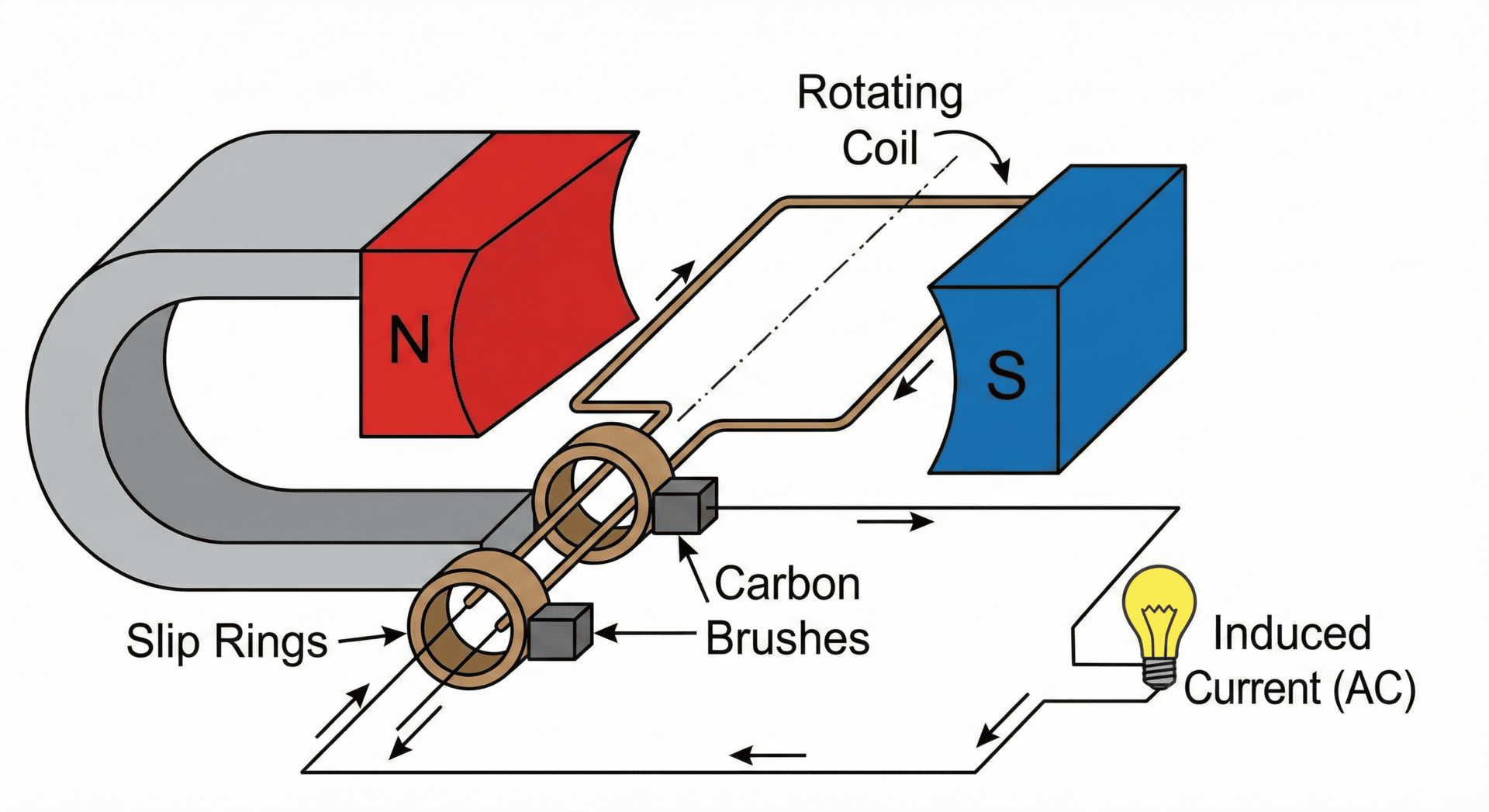

1. AC Generators (Alternators)

AC generators produce a current that periodically reverses direction. This is the standard form of electricity used in homes and businesses because it can be easily stepped up or down in voltage for long-distance transmission.

- Mechanism: They use slip rings connected to the ends of the armature.

- Slip Rings: These are continuous metal rings that rotate with the coil. Because they maintain a fixed connection to the same end of the wire, the polarity of the output changes as the coil flips through the magnetic field, resulting in a sine-wave output.

2. DC Generators

DC generators produce a current that flows in only one direction. While less common for large-scale power grids, they are vital for battery charging and specific industrial motors.

- Mechanism: They utilize a split-ring commutator.

- Split-ring Commutator: This acts as a mechanical rectifier. It consists of a ring split into segments. As the coil rotates, the commutator reverses the connection to the external circuit every half-turn. This ensures that even though the current inside the coil is alternating, the current leaving the generator always flows in the same direction.

- Brushes: Carbon blocks that press against the commutator or slip rings to transfer electricity to the external circuit.

Working Principle of Generators

Generators operate by converting mechanical energy into electrical energy through the fundamental principle of electromagnetic induction. This process relies on the relationship between electricity and magnetism, specifically how a changing magnetic environment can induce an electric current in a conductor.

Below is a detailed breakdown of how this principle is applied within a generator:

- Establishing a Magnetic Field: The stationary part of the generator, known as the stator, creates a consistent magnetic field. This is achieved using either permanent magnets or powerful electromagnets.

- The Role of the Armature: Inside this magnetic field sits the armature, which is a rotating coil made of multiple loops of wire.

- Mechanical Rotation: A mechanical source, such as a wind turbine, steam turbine, or water wheel, provides the force needed to spin the armature. This creates relative motion between the wire coil and the magnetic field.

- Electromagnetic Induction (Faraday’s Law): As the armature rotates, its wire loops "cut" through the lines of magnetic flux. According to Faraday's Law, this changing magnetic environment induces an electromotive force (EMF), or voltage, across the ends of the coil.

- Current Generation: This induced voltage forces an electric current to flow. Depending on the generator's design, this will be Alternating Current (AC) if slip rings are used, or Direct Current (DC) if a split-ring commutator is used.

- Energy Transfer: The electrical energy travels from the spinning armature to an external circuit via contact points called brushes. From there, the electricity can be used to power devices, lights, or machinery.

- Regulation: To ensure the power is safe and consistent, mechanisms like voltage regulators or governors are used to control the strength of the magnetic field or the speed of the mechanical source.

For a visual explanation, check out this YouTube video on how electricity is generated.

Energy Transformation and Efficiency

In a generator, energy undergoes a series of transformations from its source to the final electrical output.

The Transformation Chain

- Mechanical Energy: The initial input comes from a source like steam, wind, or falling water.

- Kinetic Energy: This mechanical force is converted into the kinetic energy of the rotating turbine and armature.

- Electrical Energy: Electromagnetic induction transforms that kinetic energy into moving electrons (electricity).

- Useful Energy: The final electrical energy is transferred to an external circuit to power appliances, lights, or motors.

Factors Affecting Efficiency

Efficiency is a measure of how much input energy is successfully converted into useful electrical output. No generator is 100% efficient due to various energy losses:

- Copper Losses (I²R): As current flows through the armature coils, electrical resistance generates heat, wasting energy.

- Mechanical Losses: Friction at the bearing points and air resistance (windage) against the rotating parts convert kinetic energy into heat.

- Iron (Core) Losses: Changes in the magnetic field within the iron core of the generator can cause energy loss through "eddy currents" and hysteresis.

- Sound Energy: Some kinetic energy is converted into sound vibrations during operation.

Understanding these losses is essential for calculating the overall efficiency of a power generation system and for designing more sustainable energy solutions.

Glossary of Terms

- Electromagnetic Induction: The production of an electromotive force across an electrical conductor in a changing magnetic field.

- Armature: The power-producing component of an electrical machine. In a generator, it is the coil where the current is induced.

- Magnetic Flux: A measurement of the total magnetic field which passes through a given area.

- EMF (Electromotive Force): The electrical action produced by a non-electrical source, measured in volts.

- Rectification: The process of converting alternating current (AC) into direct current (DC).

- Turbine: A machine for producing continuous power in which a wheel or rotor is made to revolve by a fast-moving flow of water, steam, gas, or air.

Summarise with AI:

You are the best,, coz you have gotten content about the topics

Hello ! Glad to hear that you’ve found the content useful!